Popular Highlights

When only a watchmaker will do

Restoration of Omega Jump Seconds Clock

|

Preproduction Display Cased 37500

|

WWII Hamilton Mod 37500

Preproduction 37500 used for final contract approval

|

|||

|

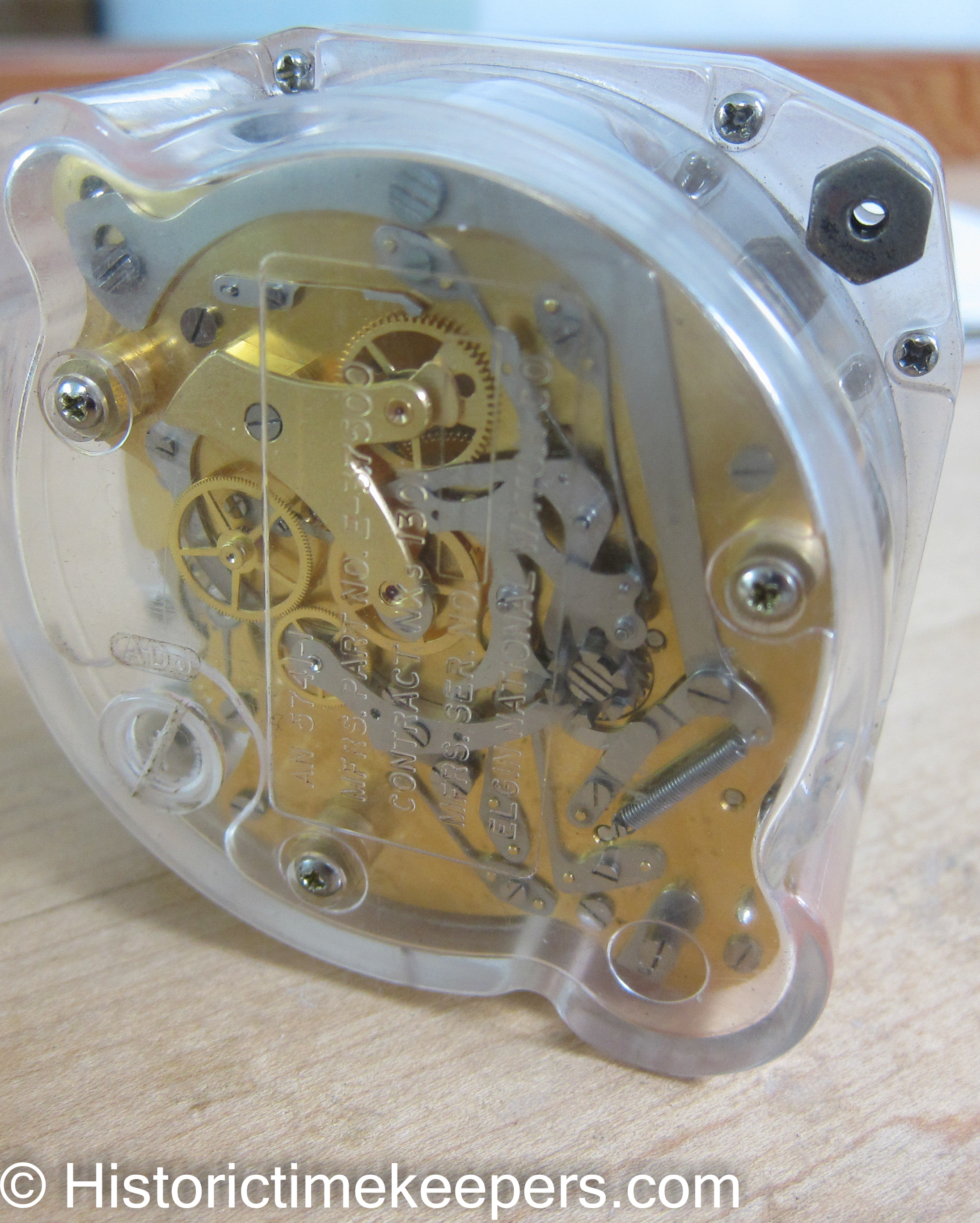

This is thought to be a one of a kind and is shown

here for your enjoyment. It is an Elgin factory cased 37500.

The celluloid injection molded case is the only one known in existence.

Note the gold washed plates. Also, there is no serial number on the top plate. It is thought to have been used to gain final approval of the design and contract for the Hamilton/Elgin 37500 aircraft issued by the USN after the Jaeger/Lecoultre became unavailable to the US forces. Interstingly, the British smuggled Lecoultre prodcut from Switzerland throughout the war' but that is a story unto itself. This clock was found with a transparent celluloid dial. Sadly, the dial had shrunk so much it literally pulled away from its mounting screws and crumbled in my hands. So I skeletonized a New/Old stock dial. I also installed new stainless steel mainsprings. The clock is fully functional and is helpful in explaining how the unit operates. Also, it demonstrates that proper technique leaves no fingerprints or lubrication smears. Having serviced/restored these clocks for over 20 years, I researched some facts that explain why so many remain even though only 40,000 were manufactured (there is a caveat to this number explained below). Of 300,000 combat aircraft manufactured during WWII, 56,000 were assigned to the USN or USMC. The total production of the 37500 went to the USN Bu Aero for distribution. Total losses for the USN and USMC were around 1,000 combat aircraft. So the majority of 37500 production survived the WWII. I suspect most were slavaged from surplus aircraft, but it is unknown how many were left in the airplane when it was destroyed. I do know these were assigned to USA helicopters during Vietnam and they were still on the P-3 equipment list in the late 1990s. Also, I do know a substantial number of unfinished but serial numbered movements are included in the production numbers; this is because I purchased at least 20 such movements deep packed and in labeled boxes from when they were taken off the production line. These clocks are a testament to US manufacturing and the use the US Government gets out of its equipment. Many of these clocks were in continuous service for over 50 years!! And they still can be put restored to service. The major losses seem to collector accident and attempts to service them without knowing how. For those unfamiliar, this clock was a replacement for the originally specified Jaeger Lecoultre A-10 found here. There were versions designed for the USAAC and the USN. The requirement called for a time of trip function, 60 minute chronograph and civil date (for use in the Pacific). The production and contract for the 37500 was quite complicated. Hamilton made plates and screws; while Elgin made wheels and the escapement. They then shipped parts to each and assemble completed units with their unique factory specific serial number and factory case. While I have not seen the contracts, I would suppose they were paid for manufacturing parts and then again for assembled units. If you think about the tolerances involved and the need to eliminate hand fitting of parts, this was an absolutely astounding feat of American engineering! |

||||