The

wheel on the left is a "repaired" winding wheel form a Jaeger LeCoultre

A-10 aircraft clock. These clocks do not have a clutch that

prevent s damage if the winding is forced backwards and these clocks

wind counter clockwise, the opposite of most timepeices. So the

windng wheels are often found with broken teeth or the winding stem is

broken. As you can see, a previous attempt was made to "repair"

the wheel by letting in new teeth. Since these it is nearly

impossible to replace so many teeth with the correct proportions by

hand, the winding action was rough and inconsistent. Parts are not

available and new one had to be made. The prepared steel blank is

on the left. The

wheel on the left is a "repaired" winding wheel form a Jaeger LeCoultre

A-10 aircraft clock. These clocks do not have a clutch that

prevent s damage if the winding is forced backwards and these clocks

wind counter clockwise, the opposite of most timepeices. So the

windng wheels are often found with broken teeth or the winding stem is

broken. As you can see, a previous attempt was made to "repair"

the wheel by letting in new teeth. Since these it is nearly

impossible to replace so many teeth with the correct proportions by

hand, the winding action was rough and inconsistent. Parts are not

available and new one had to be made. The prepared steel blank is

on the left.

The

blank is mounted on an arbor and put in the horizontal mill for cutting

the teeth. The

blank is mounted on an arbor and put in the horizontal mill for cutting

the teeth.

Spray

lubricant to protect the cutter. Spray

lubricant to protect the cutter.

Unlike

brass wheels, steel winding wheels have to be hardened and tempered. Unlike

brass wheels, steel winding wheels have to be hardened and tempered.

Here

is the finished wheel on the mainspring barrel next to the "repaired"

wheel. Operations not pictured were punching the square center

hole and running the wheel through the surface grinder to bring it to

the correct thickness. Here

is the finished wheel on the mainspring barrel next to the "repaired"

wheel. Operations not pictured were punching the square center

hole and running the wheel through the surface grinder to bring it to

the correct thickness.

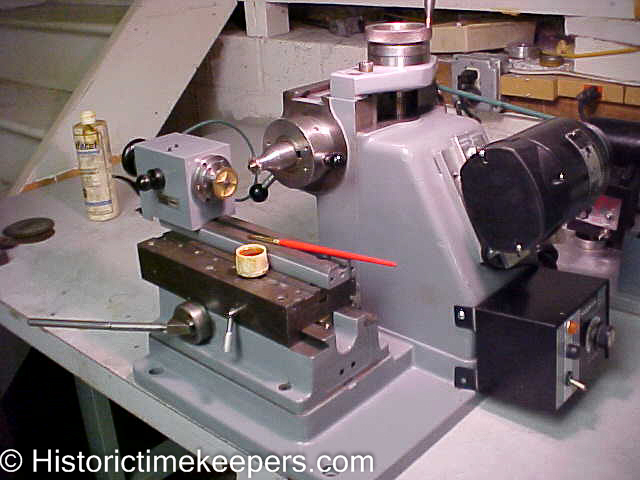

This

is what the setup looks like. You can see the set of dividing

plates to the left of the cutting set up. The correct dividing

plate is mounted on the rear of the headstock. Dividing plates are

discs with accurately located notches evenly spaced around their

circumference. Different numbered plates allow you to cut gears

with different numbers of teeth. Most sets go include plates

between 50 and 100 divisions. This

is what the setup looks like. You can see the set of dividing

plates to the left of the cutting set up. The correct dividing

plate is mounted on the rear of the headstock. Dividing plates are

discs with accurately located notches evenly spaced around their

circumference. Different numbered plates allow you to cut gears

with different numbers of teeth. Most sets go include plates

between 50 and 100 divisions.

|