Popular Highlights

When only a watchmaker will do

Restoration of Omega Jump Seconds Clock

|

Making a Bimetallic Balance |  Balance Prior to Being Split |

||

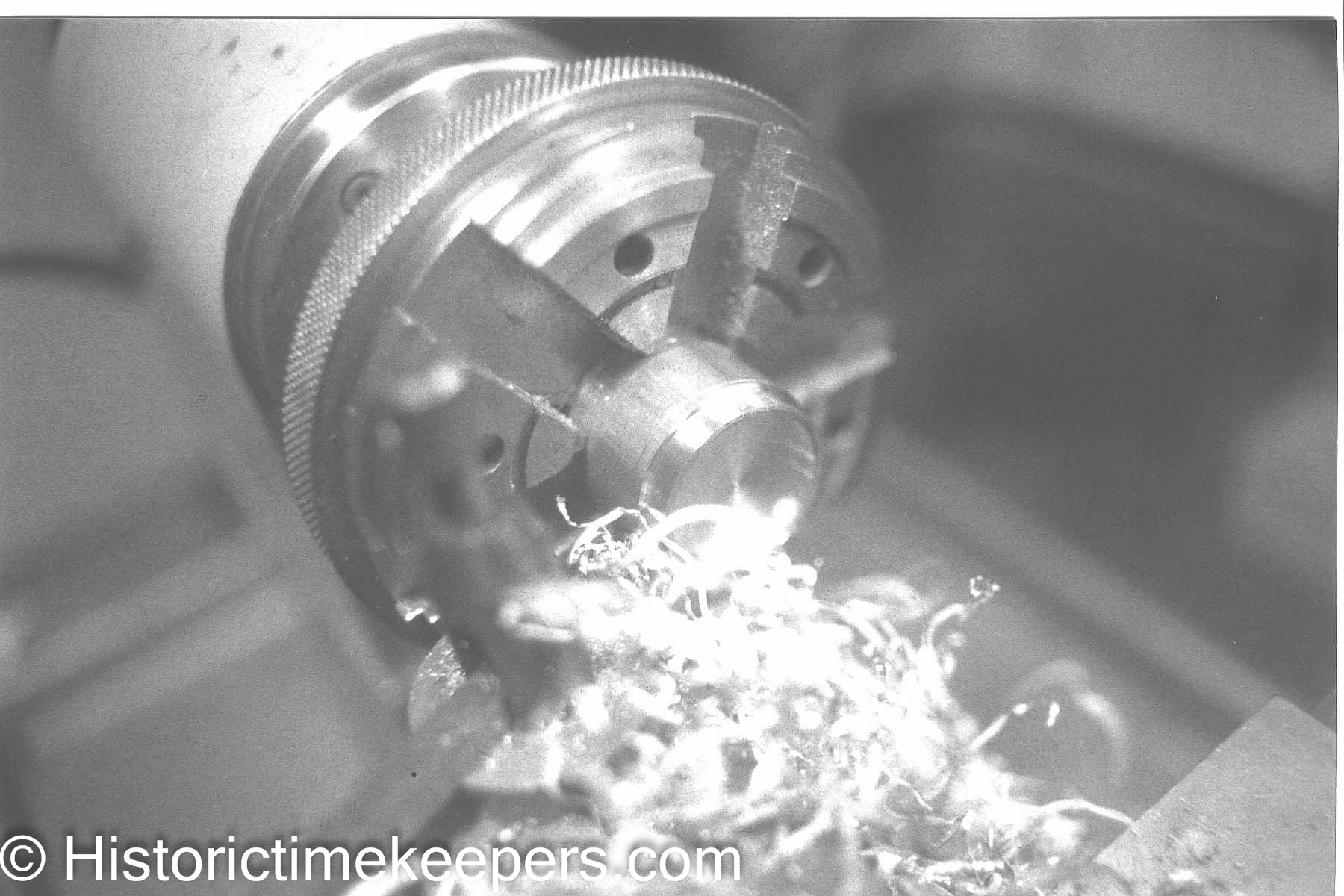

Cutting

the groove into the face of the steel slug (trapanning). This

groove will receive the brass that will become the outer lamination of

the bimetallic balance. Cutting

the groove into the face of the steel slug (trapanning). This

groove will receive the brass that will become the outer lamination of

the bimetallic balance.

The finished brass ring side by side with the machined steel slug.

Other pictures will follow. The rest of the process involves drilling and tapping the rim for the timing screws, remounting the slug to finish to size the OD, ID and depth of the floor (to the required thickness of the crossarm). I will also show the process used for cutting out the cross arm.

|

|||

The

machined steel slug. The center bore is left 1mm higher than the

groove so that the final crossarm can be a maximum of 1mm thick. A

center hole is drilled prior to dismounting the slug so that it can be

centered for subsequent machining on a cement faceplate.

The

machined steel slug. The center bore is left 1mm higher than the

groove so that the final crossarm can be a maximum of 1mm thick. A

center hole is drilled prior to dismounting the slug so that it can be

centered for subsequent machining on a cement faceplate.

Turning

the OD of a brass rod to fit inside the groove of the steel slug.

Turning

the OD of a brass rod to fit inside the groove of the steel slug.

The

Brass ring fitted into the groove of the steel slug.

The

Brass ring fitted into the groove of the steel slug.

The

brass ring has been fused to the steel slug. In essence, this is a

brazing procedure in which the brass ring is melted into the groove.

The

brass ring has been fused to the steel slug. In essence, this is a

brazing procedure in which the brass ring is melted into the groove.

The

slug with the fused brass ring is machined on a cement chuck. The center

hole drilled while the slug was initally machined is used to center the

work on the cement faceplate. The slug is faced, the outer wall of

the old groove is turned away exposing the brass outer layer.

The

slug with the fused brass ring is machined on a cement chuck. The center

hole drilled while the slug was initally machined is used to center the

work on the cement faceplate. The slug is faced, the outer wall of

the old groove is turned away exposing the brass outer layer.

The

brass ring is hammered to compress the grain. This also work

hardens the brass.

The

brass ring is hammered to compress the grain. This also work

hardens the brass.