Popular Highlights

When only a watchmaker will do

Restoration of Omega Jump Seconds Clock

|

Making a Barrel Arbor |  Finished new barrel arbor and the broken original |

||

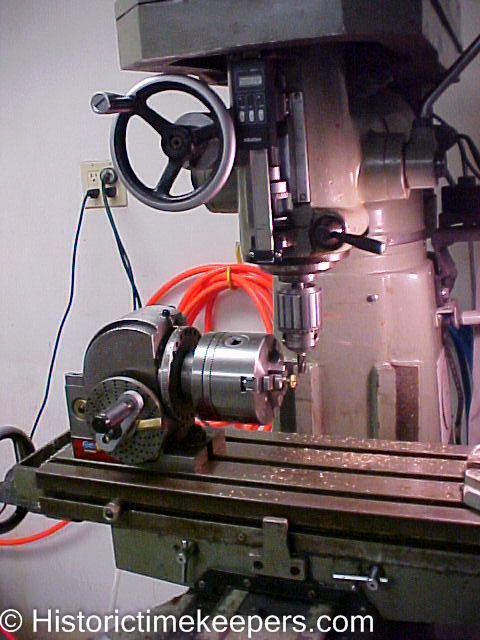

This series shows the making of an arbor for the mainspring of a chronometer. The process is the same whether for a chronometer, clock or watch. This particular project shows the virtues of the Habegger lathe and the vertical mill. While it could have been turned in the 10mm Levin, the Habegger's increased rigidity made it the better choice. I remember using the Levin ad the small 3 jaw chuck to make similar items and it was headache. The Habegger 102 turns a 3 hour chore into a one hour joy. This is why I sold the bench mounted Levin very shortly after I acqured the the Habegger. This project also makes use of the vertical mill for two operations. again, I could have filed the square on the WW lathe using the file rest and I could have drilled the hook hole in some other way. How did this arbor break? While out of its case, it is easy to mistake the mainspring arbor and setup pawl as the place to apply wind over the fusee arbor. Given the hardness of the arbor, it does not take much to snap off the square. Many owners mistakenly wind the wrong arbor when the have the movement uncased for examination or for removing the wedge that immobilized the balance during storage or shipping.

Turning the various diameters on the 8 inch Habegger.

The turned blank compared to the original.

The next few shots show milling the square for the setup ratchet..

Drilling the hole for the mainspring hook.

Now the blank is mounted in the 10mm Levin for polishing prior to heat treating. the pinion is cut.

Wrapped for hardening.

Prior to tempering and final polish.

After tempering.

|

|||